Toggle Navigation

Fully automatic, computer-operated road barrier system roll-forming line for different profiles and assembly elements. System fully cover the production of all road barrier elements (barrier beam, column, distance profiles, clamps etc. - total 7 profiles). It is created for productions of one- and two-sided barriers with different distance and column profile lengths.

Highway Guard Rail Two Wave or W beam Cold Rolled Forming Machine is designed to make the W beam or two wave guardrail in batch fully automatically.Highway collision avoidance facilities, isolation and other facilities. Mainly used for traffic security projects such as highways, primary and secondary roads, provincial roads, county roads and rural road scenic spots, large parking lots, etc.

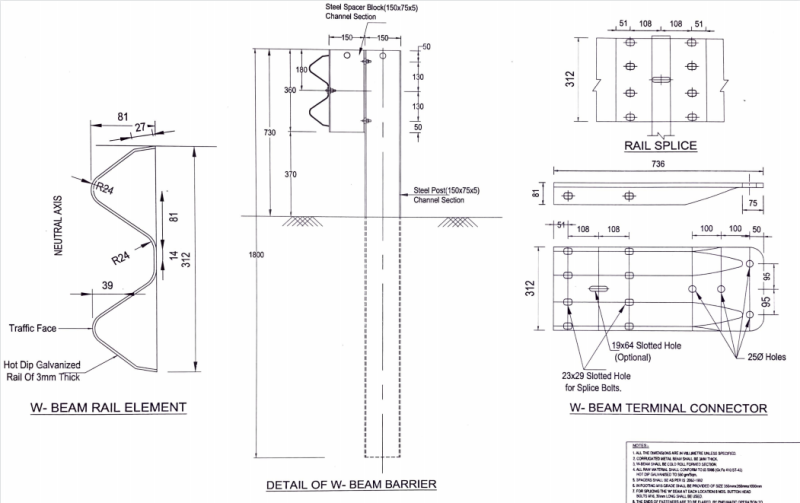

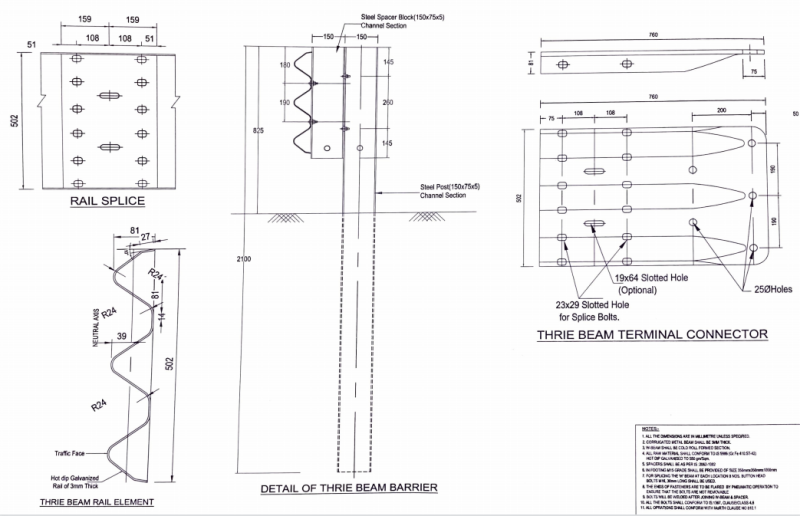

Here are some highway guardrail drawing profiles for your reference:

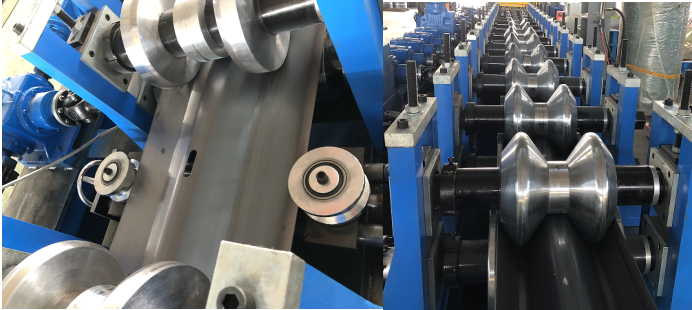

Highway Guard Rail Two Wave or W beam Cold Rolled Forming Machine:

For the guardrail machine design, we have the following types for your reference:

As to the machine design whole working flow, it could be designed as before shearing and after shearing.

The difference of before shearing and after shearing lies in that:

Before shearing will be a little faster than the after shearing.

If two types supported, no need to change the cutting blade.

But before shearing end and start will be a little sizes error.

Uncoiling ð Alignment guiding roller ð 9 rollers leveling ð hydraulic punching hole ð Panel Transport table ð Swift sheet feeding ð Photoelectrical switch ð Roller guiding table ð 15 stations roll forming ð Finished product support table.

Highway Guard Rail Two Wave or W beam Cold Rolled Forming Machine working videos for your reference:

<iframe width="650" height="450" src="https://www.youtube.com/embed/8198qUknqDI?rel=0" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" allowfullscreen></iframe>